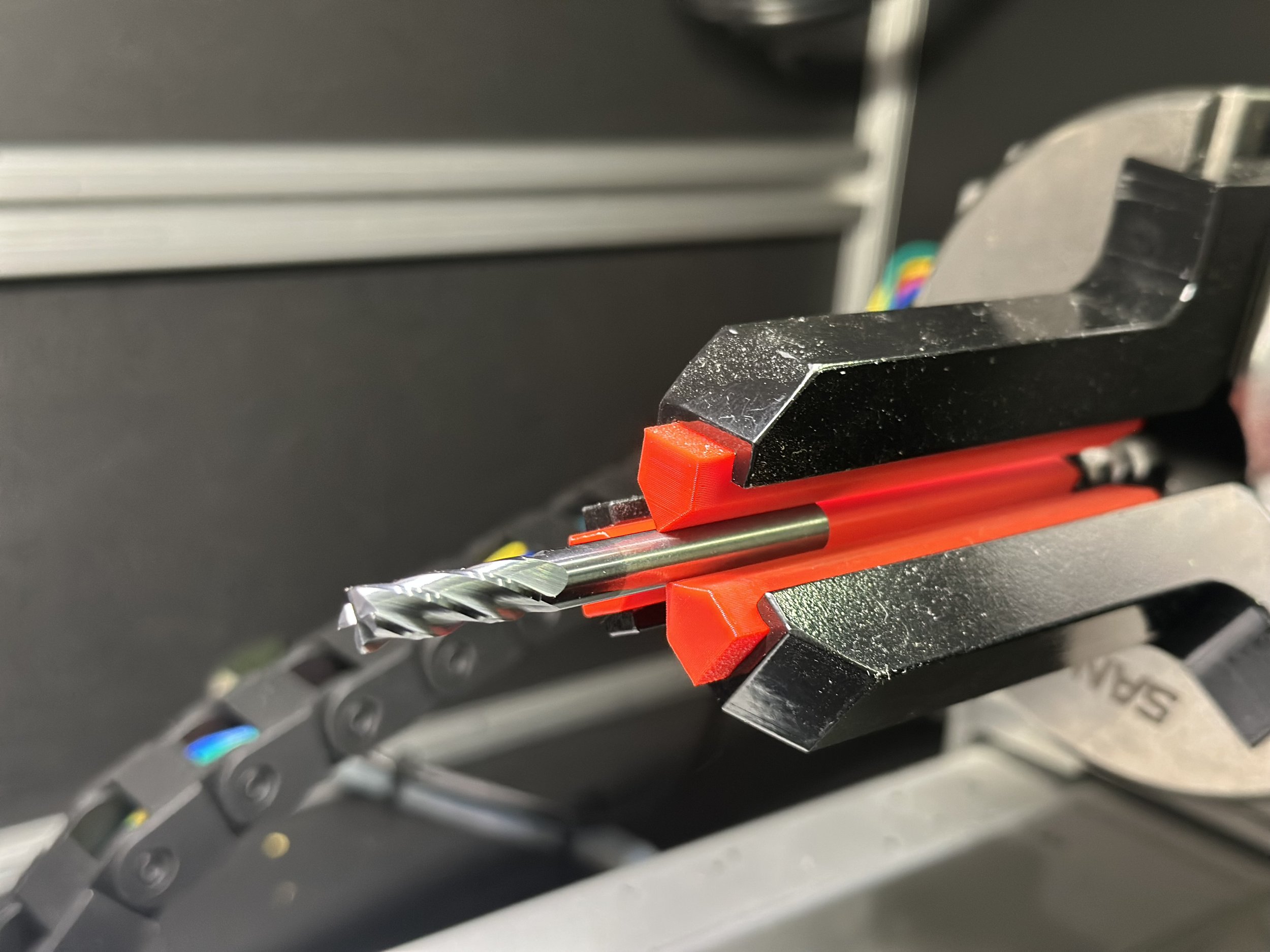

DXM100: Drill Edge Prep

Our most capable drill edge prep machine, now in a compact size.

For tools that cut with the point such as drills, gear sticks, reamers, trepans, etc.

First part, good part in hole making

Ability to run higher feed rate with reduced torque

Longer tool life

Tighter tolerance hole to hole

Eliminate run out

DXM100 Capabilities

20 edge prep sizes

Tool diameters up to 1”

Left or Right hand cutting

From single flute up to 6 flute

Ability to prep along ‘S’ Point

Drill Points in any manufacturer’s point configuration

Reamers in any manufacturer’s configuration

Gun Drills (single and two flute) in any length

DXM100 Features

Graphical touchscreen

Multicolor LED indicates status of machine / process

Physical emergency stop button

Laser beam drill point detection

Clear part door allows operator to watch process

Brushing area is enclosed to keep dust contained

Automatically indexes flutes, a new feature for 2025

Edge counter to track number of preps applied

Run in single mode or set to auto mode to restart same program when part door is closed