Even the best skate grind produces an edge burr leading to reduced glide, prematurely dull edges and dangerous lacerations for staff trying to remove them.

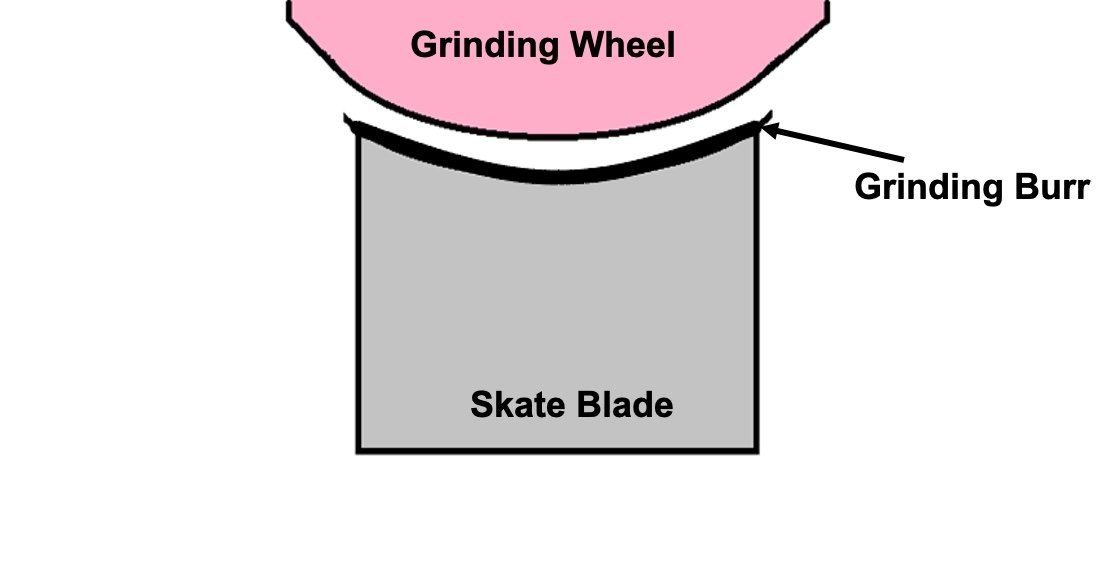

The grinding process

Grinding wheel processes will always produce grinding burrs and surface oxidation.

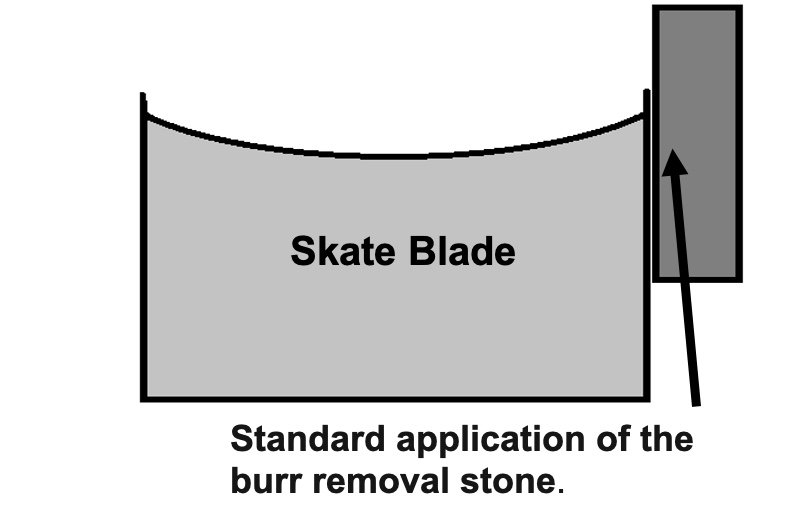

Typical stoning process

Side stoning bends the burr vertically under the blade corner.

Side stoning does not address removal of the oxidized layer.

The EdgeHone process successfully removes the grinding burrs and hones the edges in less than a minute, leaving the blade edges square and the hollow surface smooth.

The EdgeHone does not alter the shape or size of the hollow grind or the blade edges and is compatible with coated blades.

Designed by engineers with a combined 60 years experience in cutting tool edge preparation, Conicity Technologies is proud to introduce the EdgeHone, a safe and consistent method for removing grinding burrs from skate blades.

Before EdgeHone

50 x magnification photo of a blade after grinding

After EdgeHone

Burrs have been removed and the hollow has been polished.

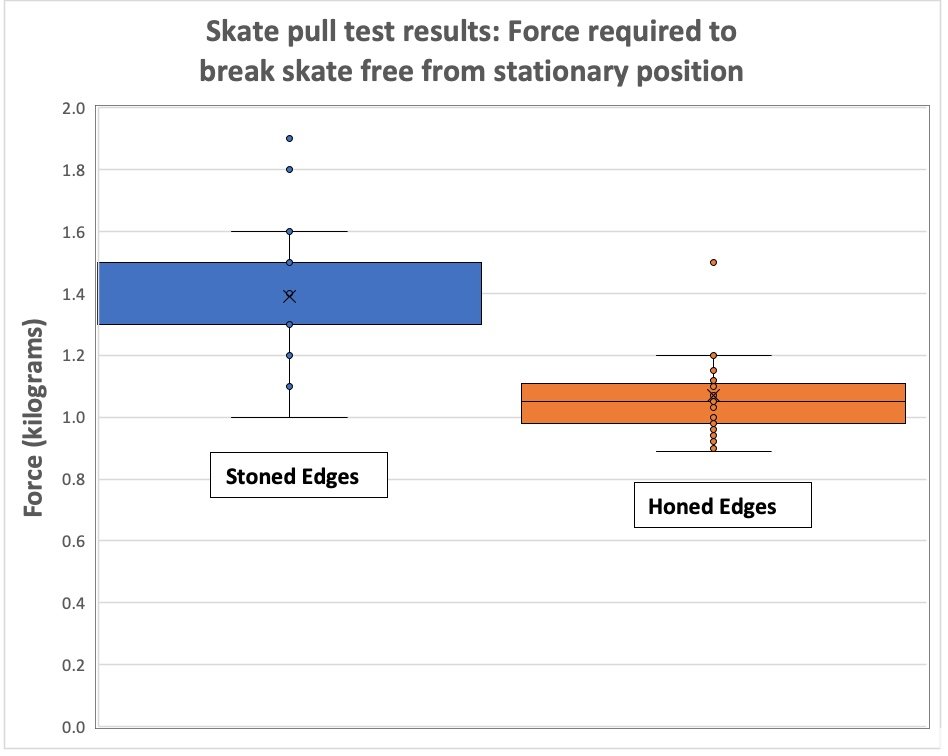

Reducing friction on the ice

Static friction is reduced by up to 30% when comparing edge prepped blades and conventional ground/stoned blades.

The reduction in friction allows the skater to start, stop, turn faster, and skate faster/further using less effort.